Pipeline Integrity & Maintenance

The first network of pipelines was installed in the 1860’s and now the continental United States contains more the 2.6MM miles of pipeline, making this system of pipelines the largest pipeline network in the world.

More than 60% of these pipelines were installed prior to 1970. Aging pipelines require regular maintenance and we are pleased to partner with companies to assist them in staying compliant with regulations and to protect the people and environment while safely transporting energy products.

Our team of experts are very experienced in pipeline maintenance and understand the sensitive nature of working with in-service pipelines. We understand the methods and needs to inspect pipelines and are proficient in all repairs.

According to PHMSA regulations, owners must perform pipeline inspections every 3 years for liquid and crude oil midstream pipelines and 5 years for gas pipelines.

Pipeline Integrity – What We Do

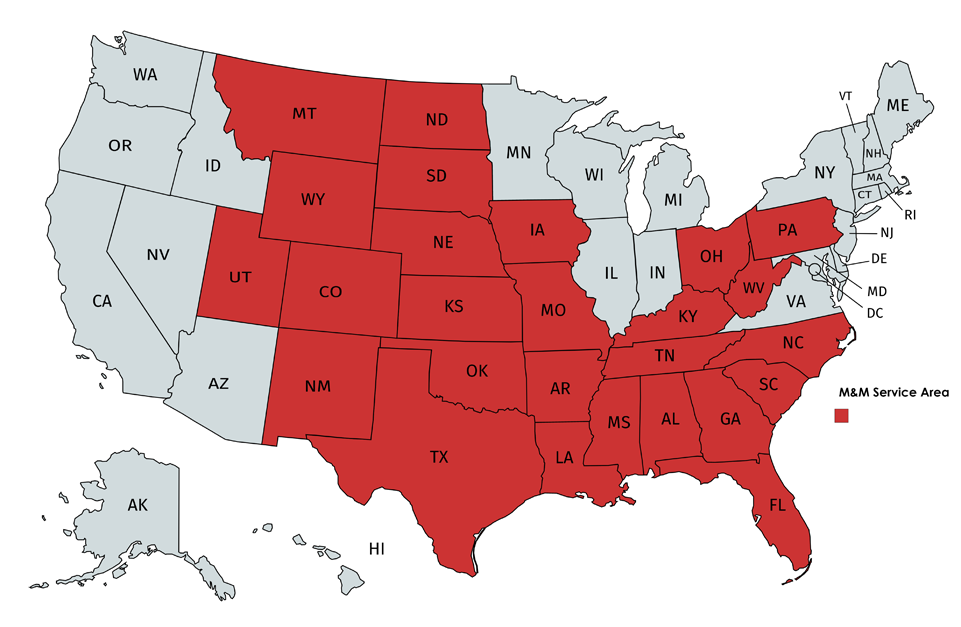

M&M and our Team have experience repairing anomalies throughout the US using a variety of methods, whether pipe replacement, composite sleeves or coating repairs.

- Hydrostatic Testing

- System Upgrades

- Make Ready (make piggable)

- Piggablilty/ Repairs (Tool Restriction)

- Anomaly Remediation

- Asbestos/Abatement

- DOT Replacements

- Pipeline Replacements

- Repairs – Type A & B Full Encirclement Sleeves (Type A & B) & Composite Repairs

- Pipeline Relocation

- Pipeline Abandonment

- Facility Modification/Fabrication

- In Line Inspection

- Recoats

- Cathodic Protection

More M&M Services

Construction

Boring